Push the process to the optimum

Production processes require a lot of effort, knowledge and creativity to operate at high performance.

Achieving performance above the industry average requires extensive extensive expertise. A comprehensive plant wide analysis identifies the feasibility and quantifes the benefits, corrective actions, execution timeline, and return on investment (ROI).

Measured Benefits

Transparent calculation methods.

Verified Results

Verification period is reliable to certify the achieved results.

Benefit based performance

Post payment is possible to pay out the investment from the economical results.

How are benefits measured?

Achieved business benefits are measured after optimization and compared to baseline.

In order to measure benefits all processes are characterized by viewing relevant inputs and outputs. Several months of operational time series data gathered provides suffucient information for precise estimation of improvements. All processes are different or operates differently so benefit calculation algorithms are are adapted for each individual process in cooperation by customer.

Energy

Decreased utility costs and specific energy consumption.

Quality

Autonomous operation to have consistent and stable product quality within specification.

Throughput

Capacity increase by fine tuning the control system to handle limits at peak performance.

Material usage

Decreased raw material, chemical or intermediate usage.

Emission

Reduced energy usage ensure that emission are reduced.

Primary benefits

Major primary return indicators that are typically easy to quantify.

Maintenance

Variability reduction would decrease the deterioration of equipments.

Operator load

Operation enabled to move the focus to the process rather than controlling it.

Asset life

Less mechanical stress on the equipments will increase the equipment lifetime.

Alarm

Significantly reduce the number of deviation alarms by tighter controls.

Safety

The control system is more responsive on operational disturbances.

Availability

The production is less constrained by lost production time.

Secondary benefits

These are similarly important indicators of effectiveness, but their determination typically requires a more comprehensive assessment over a longer period of operation.

Remote Data Analysis

Connect with us, based on your data supply we investigate your problem remotely and deliver the results.

Consultancy

We mitigate risk and drive success by performing feasibility studies, calculating returns, planning resources, and establishing guarantees.

Feasibilty Study

Feasibility

For further decision-making preparation, we determine if the identified problem is solvable, and then assess the viability and sustainability based on the resources required for solution or different solution scenarios.

Benefit Estimation

After identifying the benefit carriers, we quantify the financial and material results can be achieved, and assess their confidence as well.

Resource Allocation

The time and engineering requrements are determined.

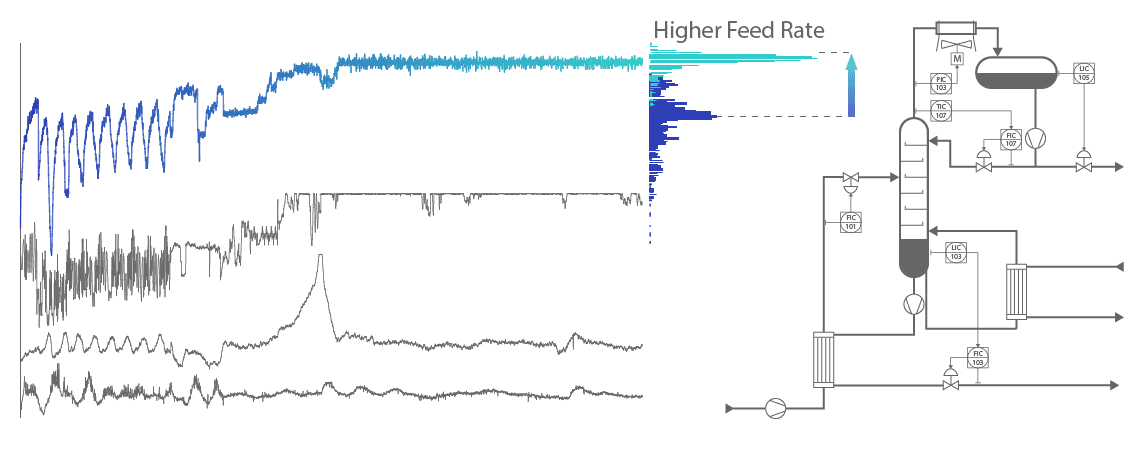

Increased Throughput example

Prior to control optimization the operation was only possible at low rate. Process stabilization enabled an increase of the feed rate and smooth operation at highest production throughput with existing field equipments.

Why choose MaxFlow?

A holistic approach is developped to handling the complexity of production and control systems.

- Start-to-finish solutions

- Data driven proof of solution and result

- Minimized Risks

- Guaranted benefits

- Fast world-wide delivery

- Trained Professionals

- Insured delivery

Approch

Holistic

Step By Step

Each performance improvements reveals further barriers which were hidden before.