Process Performance Audit

Push the process to the optimum

Production processes require a lot of effort, knowledge and creativity to operate at high performance. Pushing the production processes above the industry average requires a vast amount of knowledge. We can help to make your process perform optimally.

We take on the risk of performance improvement by analysing your production process for free and if real potential for improvement exists implementation follows and achieved benefits are measured. You will know exactly what you are paying for and payment will be due only after the project has returned it's value.

Achieved by adjusting your control system only. Better control means that it is the control system that adjusts the process, leaving the operation personnel to focus on directing the system. This frees up the operator's time so they can turn their focus to better operation of the process.

Push closer to optimum. Achieving optimal operation is not that easy, because the plant needs to be pushed to a point where it has never operated before. With the extensive data analysis and statistical tools we use it is possible to calculate new operational targets which give the process the same safety margin it had before.

Measured benefits

Each benefit category is assessed and measured.

Verified Results

Specific tests are made to certify the achieved results.

Paid on delivery benefits

We are confident about delivering the results we promise so that payment can be based upon quantified benefits.

How are benefits measured?

Achieved business benefits are measured after optimisation and compared to the performance before.

In order to measure benefits all processes are characterised by viewing all inputs and outputs. Several of months of operational data gives enough information to make precise estimation of improvement. All processes are different or operate differently so benefit calculation algorithms are adapted for each individual process in cooperation with you.

Benefits

Typical business benefits are assessed and delivered. Some benefit categories are industry and process specific. During the initial consultation process only the categories which deliver tangible business benefits are assessed.

Energy

Less specific energy consumption and decreased utility cost.

Quality

Stable product quality with good repeatability.

Throughput

Greater ease of operating at peak performance whenever needed.

Material usage

Lower input of chemicals required.

Operator load

The operators can turn their focus to the process rather than controlling it.

Maintenance

Decreased maintenance due to significantly decreased variance.

Asset life

Less stress on process equipment, increasing its lifetime.

Alarm

Significantly reduced frequency of alarms.

Safety

Your process control system is the first level barrier to any safety risk.

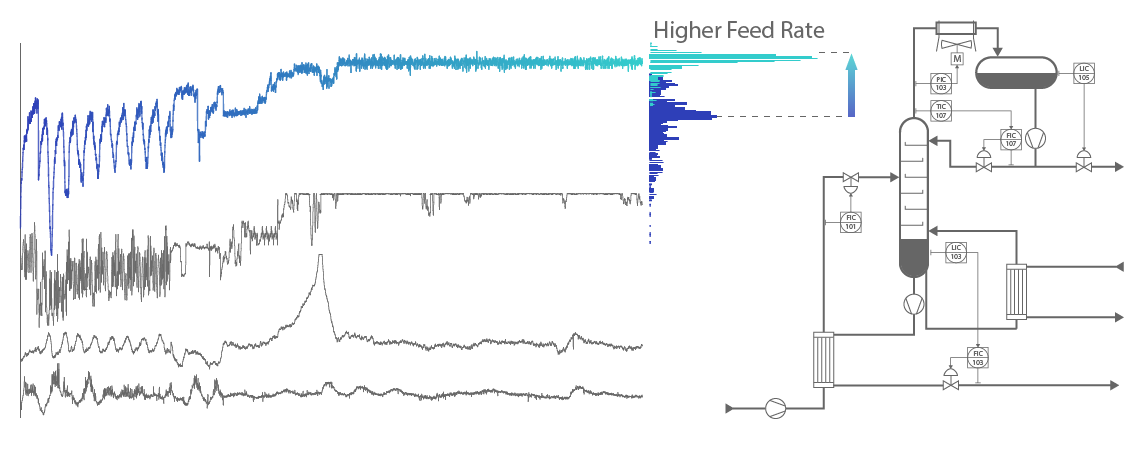

Example - Increased Throughput

Prior to our process, operation was only possible at a low rate due to equipment uncertainty. Process stabilisation enabled an increase of the feed rate and operation with the highest production throughput.

If you have questions or are interested in details, we are here to listen and answer.

Typical data requirement

Data analysis usually requires the following data inputs. If you send us the design documentation we can prepare a Data Request Requirement for you.

A custom non-disclosure agreement is available on request.

|

|

Time series data |

|

Laboratory data |

|

|

Operator schematics |

|

|

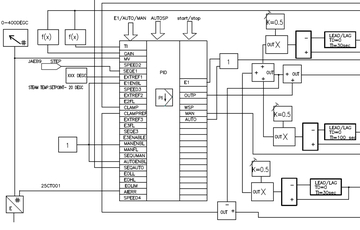

Process control system configuration |

|

|

Process description |

|

|

Piping and instrumentation diagram |

|

Process flow diagram |