Process Start-up Service

Stable operation from the beginning

A well-operating process control system protects the process.

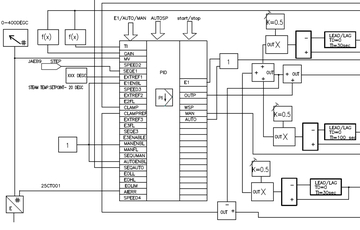

Each process plant has its own life cycle. On a newly-built plant in a green field project, our Start-up service can deliver significant advantages in the case where the technology begins with just the assembled equipment and an implemented control system. The default PID control setting are insufficient for effective compensation, or in many cases cause oscillations in the process. During our start-up service a large number of loops are quickly investigated and put into a designed control mode for a short period of time, allowing the operators to turn their focus to the process rather than manually controlling each individual process value.

Stable control

Enable normal operating conditions as designed.

Problem verification

Identify and verify root causes of the problems which arise during start-up.

Smooth start-up

Reduce the risk of process start-up with better performing controls. Decrease the demands on the project commissioning team.

When to consider...

For both new and existing technologies it is a necessity to have periodic turnaround, modernise the automation system, and even upgrade the base technology itself. In every case when parts of the control or process are modified, replaced or migrated, efficient application of our Process Start-up Service in order to renew the the integrity of system is recommended.

Benefits

Typical business benefits are delivered and assessed. Some benefit categories are industry and process specific. During the initial consultation process only the categories which deliver tangible business benefits are assessed.

Protect investment

The process control system safeguards your investment.

Normal operation

No more delays due to under-performing controls. Early on spec production.

Operator load

Less focus on control and more focus on operation.

Optional Services

These optional features are important for effectiveness. Depending on the project phase, the earlier we are involved in the start-up project, the more potential is available.

Control Design Inspection

Comparison of the operation of the process with its design can highlight critical control parts. Our early involvement in the project helps to avoid initial control design malfunction.

Initial Tuning Set

Before Start-up we deliver preliminary settings which enable all control loops to be placed into AUTO mode before the control system is fine-tuned.

On Site Support

When several partial but interacting parts of the whole process are due to start sequentially, our On Site Support offers valuable engineering assistance with continuous 24/7 availability.

Typical data requirement

Data analysis usually requires the following data inputs. If you send us the design documentation we can prepare a Data Request Requirement for you.

A custom non-disclosure agreement is available on request.