Solutions

Improvements in Productivity

Many productivity and operational problems can be solved by making the process control system better performing. A better performing control system can result in stable operation, better disturbance compensation, faster setpoint response, increased safety due to stable material and heat balance. Any problem that has an effect on your process control performance will be revealed and this enables the development of a solution for you.

Applicable for

Every Industry

Wide industry coverage.

Every Process

Wide range of processes with many solved problems.

Every Control System

Experienced with all major control system manufacturers.

The foundation of a good control is the same across all industries, processes and control systems. There are specialities in each industry which are key to understanding the depth of a problem, but control theory applies equally in all cases. Discover the most common problems we can solve or contact us to get a custom solution developed.

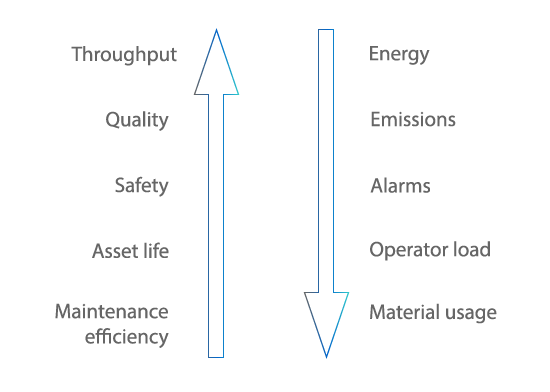

Production efficiency

In order to achieve the best every possible aspects of operational efficiency should be assessed. Not all the benefits are applicable all the time. During our process examination, each facility and benefit is evaluated. This individualised procedure ensures the greatest potential discoveries and can deal with all sorts of conditions across industries and production processes.

Optimisation directions

There are many potential factors for efficiency improvement. It is preferable to reduce some and increase others, but usually most of them work against each other. Our complex analysis methods carried out by an experienced consultant evaluate all the possibilities. In general cases the combined direction of movement of dominant factors ensures the greatest business results.

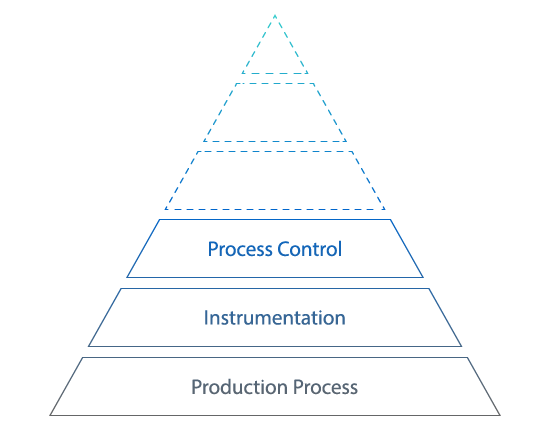

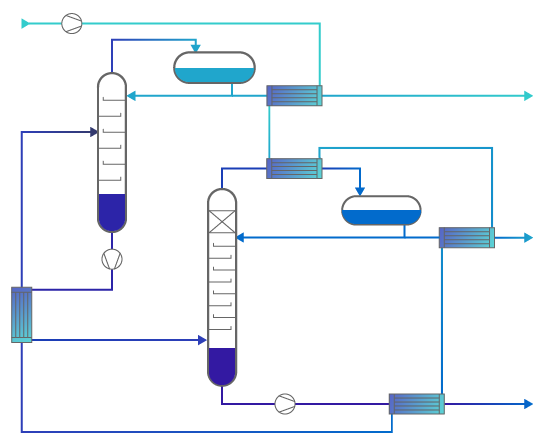

Building from the ground up

A production process is only as good as its control. Improved control makes the process easier to operate and more able to handle normal operational changes seamlessly. The performance of the process can be limited by the performance of both the instrumentation and the controller.

Our step by step procedure makes sure that each level is assessed and improved up to its maximum. If each layer is functions at maximum, the overall system performance will be highest, regardless of complexity.

Eliminate Excess Variability

Variability is the statistical distance from the control target. Every case like disturbance, saturation, oscillation, and device malfunction increases variability. Therefore this single indicator is capable of measuring any performance deviation. Our unique process data analytics can identify and verify the sources of variability. Once every details is known, it is our task to implement all the necessary changes to reduce variability to the absolute minimum.

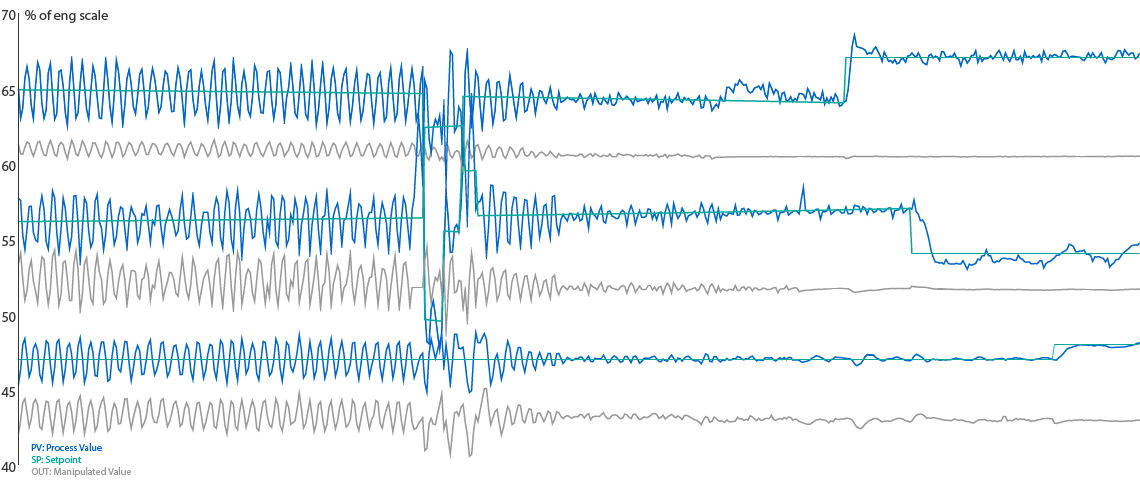

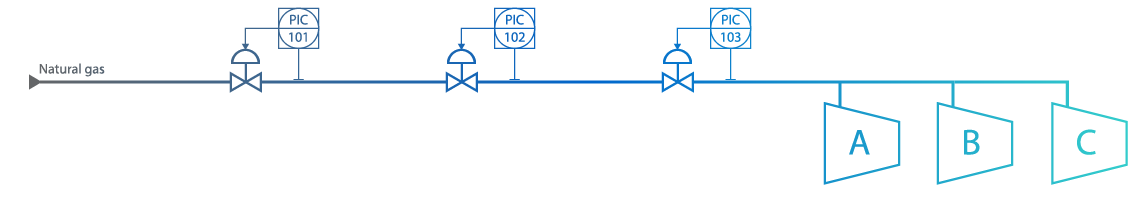

Work with interacting systems

Connected systems can easily propagate any variance. It is very common for highly interconnected systems to develop permanent oscillations which are hard to assess and eliminate. A complex system-wide analysis is required to find the real cause of these oscillations, which could affect a large number of signal at the same time.

The time series data below shows three controlled variables from an interacting system which had a permanent oscillation. After the oscillation was stopped, all the variables were controlled individually. In the final step all three variable targets were changed with no recognisable effect on the others, however the interaction still exists in the background.

Process design complexity

Production processes are becoming more and more efficient, for example more and more heat exchangers are added to the initial design to recover more waste heat. Any additional component added to increase efficiency introduces a connection between process areas. The number of interaction effects increases exponentially and spreads over multiple process areas.

We have experience of dealing with these complex dynamical interactions over many years.

Speed up

Under-performance of process cells is frequently caused by poor response combined with inherent interactions making the process unstable. This phenomena occurs when the process can't follow the lead signal without oscillation, like the master pressure signal of a boiler, or other common remote setpoints from upper level controls. We can speed up the response of the complete process cell to be able to follow the rate of the master signal, but in a stable way.

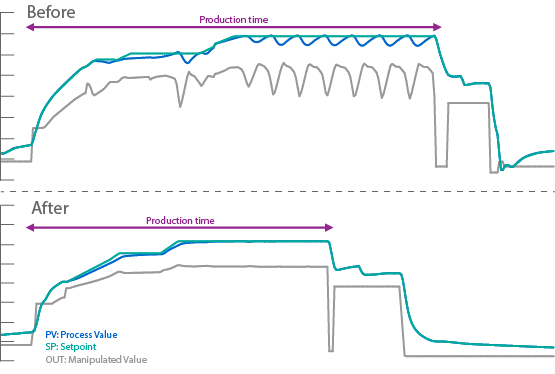

Stable and fast response

The time series data shows how the process is proven to work faster and more smoothly in accordance with the lead signal, after our services were applied.

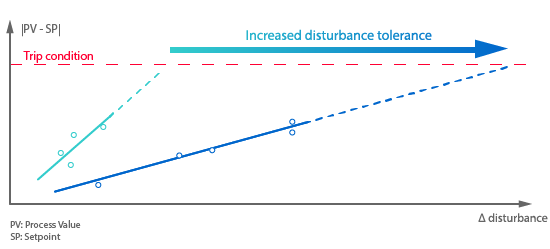

Trip prevention

When a process is working, operational incidents happen, like feed material drops, process shut-downs, flaring, blow downs and other severe disturbances. We uncover the process and control-related barriers in order to reveal any possible control response improvements. Significant improvements can be realised.

Better compensation of operational disturbances

Setpoint changes of the pressure header originally caused trips, and operation was strongly limited by trip conditions. After improvement the permitted size of a step in pressure became higher with adequate compensation. In this case the improvement resulted in significantly increased disturbance tolerance.