Our contribution to your efficiency

An offer for European companies.

We perform extensive data analysis remotely at no cost or commitment from your side. This approach helps to identify the potential improvements which will generate the greatest possible benefits.

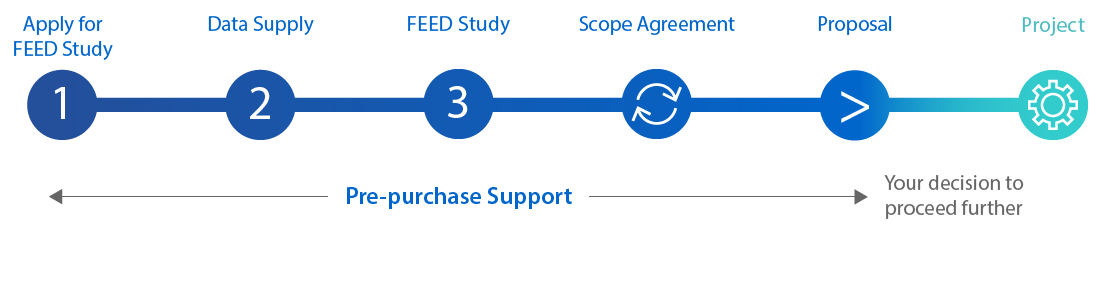

1

Apply for a FEED Study*

to identify any potential for optimisation and the economic benefits that derive from it.

A FEED Study gives you the confidence that we are capable of delivering the solution even before you make any commitment or decision. This workflow creates trust and transparency.

Example Scenarios of the Study

Most typical problems that we analyse involve enabling production plants to reach new highs in optimal operation:

-

Controllability problems due to any root causes (oscillations or slow disturbance response)

-

Oscillations of any scale

-

Quality problems (limit violations or product giveaway)

-

Unexpected shutdowns

-

Safety events

Available in Europe

Typically three datasets are required to carry out an investigation:

|

|

Time series data |

Include all the TAG names that are relevant for the investigation. If required, a data export file may be provided with all the necessary tags after submission of operator schematics.

|

|

|

Operator schematics |

The operator schematics should contain the TAG names.

|

|

|

Process control system configuration |

Generally PID controller PV range, OUT range, gain, reset, rate and filter time parameters are required. A data export file is provided after the submission of operator schematics.

|

Dedicated Help

Our engineers can help you to prepare the necessary files and easily export the necessary data from various systems.

3

Deliver FEED Study

Identifies optimisation potential

Applying industry-specific knowledge and advanced mathematics to the time series data, almost any kind of root cause can be diagnosed. Our experts look for various optimisation possibilities in your control system to develop a custom-engineered solution. We deliver an Assessment Report containing all the identified improvement possibilities.

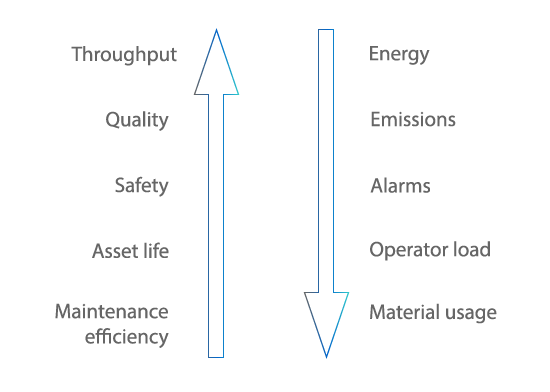

Strong Foundations

Engineering practice has proven that poor control performance diminishes operational efficiency. Improving control performance potentially leads to decreased operational costs, improved KPI's, and better safety margins in many ways. Better control means the production process does what you expect from it, under any circumstances.

Supporting the greatest efficiency in Europe!

Countries list where the program available. (Austria, Belgium, Bulgaria, Croatia, Cyprus, Czechia, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, United Kingdom)

Initiative starts 15. January 2020 and finishes upon termination.

MaxFlow reserves the right to apply changes.

Any inquiry can be cancelled by MaxFlow.

**General Non-disclosure Agreement terms applied on uploaded files.